A Johns Hopkins chemical and biomolecular engineering student design team, Lost in the Sauce, has created a prototype of a biodegradable condiment packet that can easily be recycled and could help eliminate the waste generated by today’s ubiquitous single-use packets. An estimated 850 billion condiment packets are discarded yearly, with only 10% being recycled due to their dual plastic and aluminum construction, making separate recycling difficult.

Creating biodegradable and compostable packaging for liquids is a challenge. According to the students, several companies have tried to tackle this problem, but none have been able to produce packets that work with liquid components.

Lost in Sauce’s packets are manufactured from cardstock paper dipped into a whey protein isolate solution (a byproduct of the dairy industry) that has been chemically manipulated to form a gel-like structure, creating a barrier between the paper packaging and oxygen.

“Once it dries, it creates a watertight seal around the cardstock. The material can then be folded and cut to create a condiment packet,” said team member Mira Amin.

The team’s product plan placed third in the General Ventures category of HopStart 2024, the Center for Leadership Education’s annual event challenging students to develop a business plan around a novel idea and pitch their plans to industry leaders. The students will present their prototype at the Whiting School of Engineering’s annual Design Day on May 1.

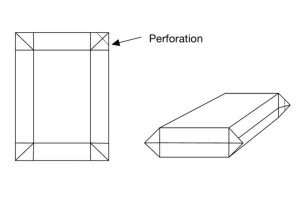

A schematic of the sauce packet design.

One thing that sets Lost in the Sauce’s approach apart is the team’s product’s shape. Unlike the flimsy packets traditionally used for hold ketchup, mayonnaise and other condiments, Lost in the Sauce’s container resembles a small juice box.

“The shape allows the package to be produced using existing manufacturing methods for other products like juice boxes and milk cartons,” said team member Evan Edelman.

The students are now exploring the addition of a natural plasticizer, such as beeswax or vegetable oil, to improve the packets’ water-barrier properties and make the gel a bit easier to handle.

“This is necessary to ensure the cardstock is not disintegrated by the condiments inside,” said Alastair Powers.

The idea for the product stemmed from the amount of misinformation about recycling the team encountered during the product brainstorming stage.

“At first, we found several sources indicating that pizza boxes were not recyclable. We thought that was absurd and it turns out it was: Pizza boxes are recyclable,” said member Noah Zahn. “So, we started thinking about the sustainability and recyclability of other common single-use items and learned about the unsustainability of condiment packets.”