Children are taught from a young age that burping is impolite but—at least judging by cows—Mother Nature seems to have missed that memo.

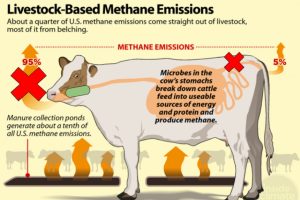

Methane-filled bovine burps (and flatulence) are so prevalent that they account for up to 2% of the climate-changing greenhouse gases emitted annually into the atmosphere from the United States. The culprits are cows’ multi-chamber digestive systems which teem with microbes that use gas-producing fermentation to break down tough plant material like hay and grass.

For their senior design project, a team of chemical and biomolecular engineering students is exploring the use of a chemical to curb cattle methane emissions at the source: the animals’ digestive systems. The students will present their concept at the Whiting School of Engineering’s annual Design Day on May 1.

“Our project, BelchBlocker, is conceptualizing a liquid feed additive for beef cattle that utilizes the chemical bromoform to inhibit the process metabolic process that produces methane. There are currently no real solutions to this problem,” said team member Will Sykes.

The team’s conceptual approach was inspired by an article that team member Kyle Fisher read, noting that adding seaweed to modern cattle feed showed promise in drastically reducing livestock methane production.

“From there, we identified the active chemicals in seaweed that were causing that methane-neutralizing effect and decided to focus on one of them: bromoform,” Fisher said.

The team used a specific type of mathematical equation known as a flip-flop pharmacokinetic model, along with some basic rate equations, to simulate the effectiveness of their bromoform additive in reducing methane production in cows. The goal was to understand how the additive would interact with the cow’s digestive system. To help calibrate their model to real-world conditions, the team also incorporated previous research on how much methane cows typically exhale.

Although the students’ simulations showed promising results from using bromoform as a feed additive, the team members say they will not try to develop their approach as a real product.

“We will not be trying to develop this in real life for a few reasons. One is that major companies are trying to do similar things that would likely beat us to market. Another is that feed additives are difficult to get regulatory approval for and our lack of access to agricultural labs,” said team member Aaron Winston.

Stephen Farias PhD ’14 and the team’s adviser, was impressed with the students’ work.

“It is exciting to see a student concept that is being paralleled by so many major research initiatives and companies. Most of those concepts weren’t public when they started this project so it is a great validation for their idea. Hopefully we get to enjoy some methane emission-free burgers soon!” said Farias.