Suffering from strep throat is not only physically painful but getting it diagnosed can also be a hassle. Patients must visit the doctor to undergo an unpleasant throat swab test, then make an additional trip to a pharmacy to fill an antibiotic prescription—all while feeling sick.

A team of chemical and biomolecular engineering students at Johns Hopkins Whiting School of Engineering is working on a novel product concept: simply gargle with saline, spit the solution into a container, and dip a test strip into the tube. Presto! A result in fewer than 20 minutes.

“Think about how easy it is to test for COVID-19 these days and apply that to strep throat,” said Alex Snyder, who worked on the project with Joseph Kim, Yuseong (Nick) Oh, and Gabriele Pierre for their engineering senior design project. “That was our thinking.”

The student team developed the concept for its Product Design class and will present its theoretical approach at the Whiting School of Engineering’s annual Design Day on May 1.

The keys to the student team’s approach are components designed to make home testing easy, straightforward, and fast.

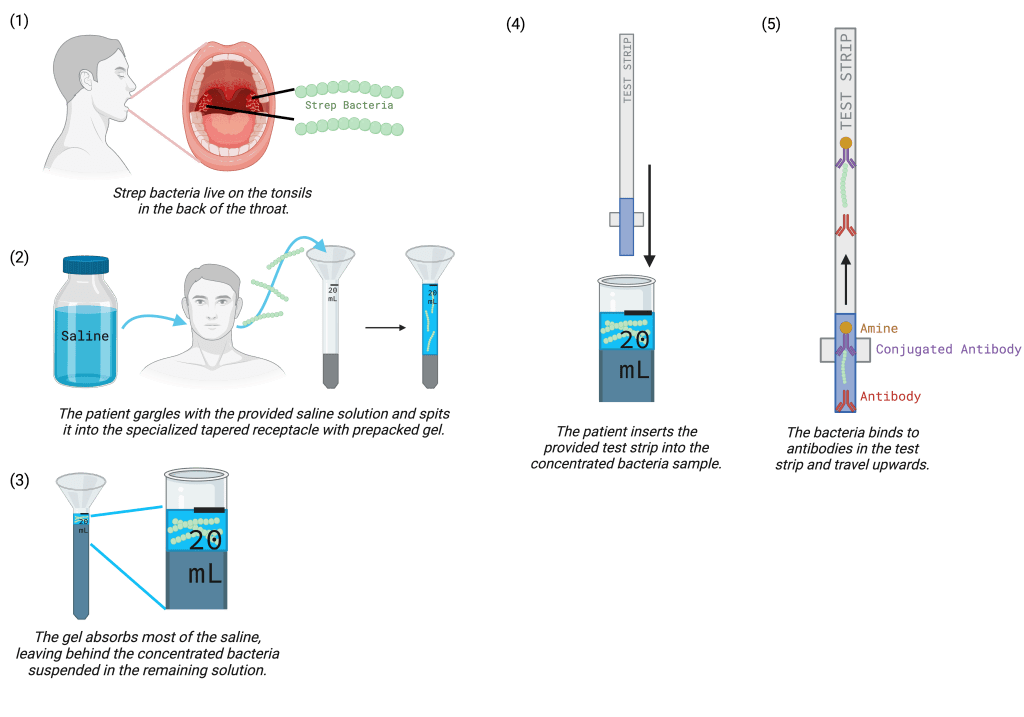

“Patients will gargle a saline solution and spit into a collection tube containing a special polymer that rapidly expands as it absorbs water, while leaving larger particles like strep bacteria to concentrate at the top,” said Oh. “Next, a lateral flow immunoassay (LFIA) strip is inserted into the tube’s concentrated solution.”

StrepCheck’s LFIA strip includes antibodies and reagents that bind to strep bacteria to show a visible test line, similar to a rapid COVID-19 test. (StrepCheck also includes a control line to confirm that the test is functioning correctly.)

“The proposed components of our test strip are based on existing strip technologies from multiple strip tests but optimized for our product’s specifications,” said team member Kim. “This includes a nitrocellulose membrane and strep antibodies with conjugated colloidal gold particles.”

To further enhance StrepCheck’s detection accuracy, the group proposes an app that that would be used scan the LFIA strip after immersion in the concentrated solution. They say that this digital tool would enhance their product’s accuracy by making it 1,000 times more sensitive to the presence of strep antigens than other rapid strep tests on the market, which also require healthcare professionals to administer.

The student’s advisor, David Gracias, a professor of chemical and biomolecular engineering, praised the team’s conceptual approach to solving a difficult problem.

“Developing at-home diagnostic tests for common infections can improve health outcomes while also saving time and money and this is the major engineering challenge being addressed here. The students did well in thinking about all the critical elements right from sample acquisition to pathogen concentration and finally testing and analysis,” he said.