Ashley Farris, a first-year PhD student in Grayson’s lab, is trying to develop a method for delivering oxygen to stem cells as they populate and replace the plastic bone scaffold. Her work is made possible through funding Grayson received from the university; he was recently selected as one of 37 early-career researchers from across the university system to receive a Catalyst Award of up to $75,000 to help them kick-start their work.

Farris’ plan is to use plastic beads—the size of baking soda crystals—filled with oxygen under pressure that slowly release the gas over weeks or months.

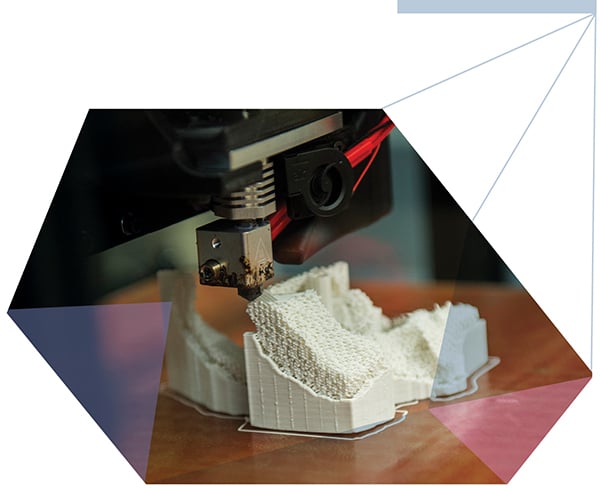

To produce a precisely calibrated oxygen level, the beads—called microtanks—will be embedded in the scaffold during the 3-D printing process. Farris says her toughest task is designing the slow-release polymer shell for the tanks, but she is optimistic about the work.

She says she was attracted to the world of tissue engineering because it’s at the interface of many different fields. “You have materials scientists, clinicians, chemists, and biologists all working together to solve the same problem,” she says.

Whiting School Dean Ed Schlesinger says that Grayson’s work, which holds the promise of changing lives in “dramatic and immediate ways,” could only be done at a school like Johns Hopkins, where the skills of researchers from so many different fields can be applied to medicine.

“If you think about the work he’s doing, it is materials engineering to develop the scaffolding materials,” Schlesinger says. “It’s biology and chemical engineering to encourage the growth of the tissues that have to replace that artificial scaffolding. It’s imaging and computer science to design the prostheses. It’s the surgery and the medicine that’s involved in the actual deployment of these prostheses. It’s the communications with the surgeons and with the physicians to understand what the issues are and what needs to be done. If you really think about all the aspects, it is remarkable.”

To provide the infrastructure for this approach, Grayson is in discussion with colleagues about creating an institute for craniofacial reconstruction, which would include a 3-D printing facility and other labs for preparing facial bone implants for surgery.

As Grayson tries to orchestrate the science and funding for his vision, he says he tries not to lose sight of the ultimate goal. Every day, he says, he and his research team “never forget why we do the research.”

“This is going to revolutionize [life for] cancer patients, trauma victims, soldiers coming back from wars, accident victims, or even children with missing bones,” Grayson says. “We are going to change the face of medicine.”