When Bill Haris, MS ’16, first walked into his human-robotics interaction class in 2015, he couldn’t have predicted that this was the moment that would ultimately set him on the path to his current position with the U.S. Navy.

The course was designed by Bob Armiger, MS ’06, and Jeff Lesho, MS ’89, PhD ’03, both of Johns Hopkins University’s Applied Physics Laboratory, as a way to connect master’s students with the duo’s groundbreaking work on the Defense Advanced Research Projects Agency’s Revolutionizing Prosthetics project.

“When they showed us what they were doing with their prosthetic limb program, I approached both instructors and said, ‘How can I get into this?’” recalls Haris, who then embarked upon a two-semester-long independent study project.

Haris quickly learned from Armiger and Lesho that in the world of prosthetics, there are two extremes. On one end, there are thought-controlled, highly dexterous devices that are very expensive to produce. On the other, there are prosthetic limbs printed using 3-D technology. They are a lot cheaper to create but are also much less responsive.

“Bill’s project was really about connecting the two dots,” says Armiger, “meaning, how can we take some of the lessons learned from the advanced prosthetics [program] and bring them to the very low-cost prosthetics field to improve the quality?”

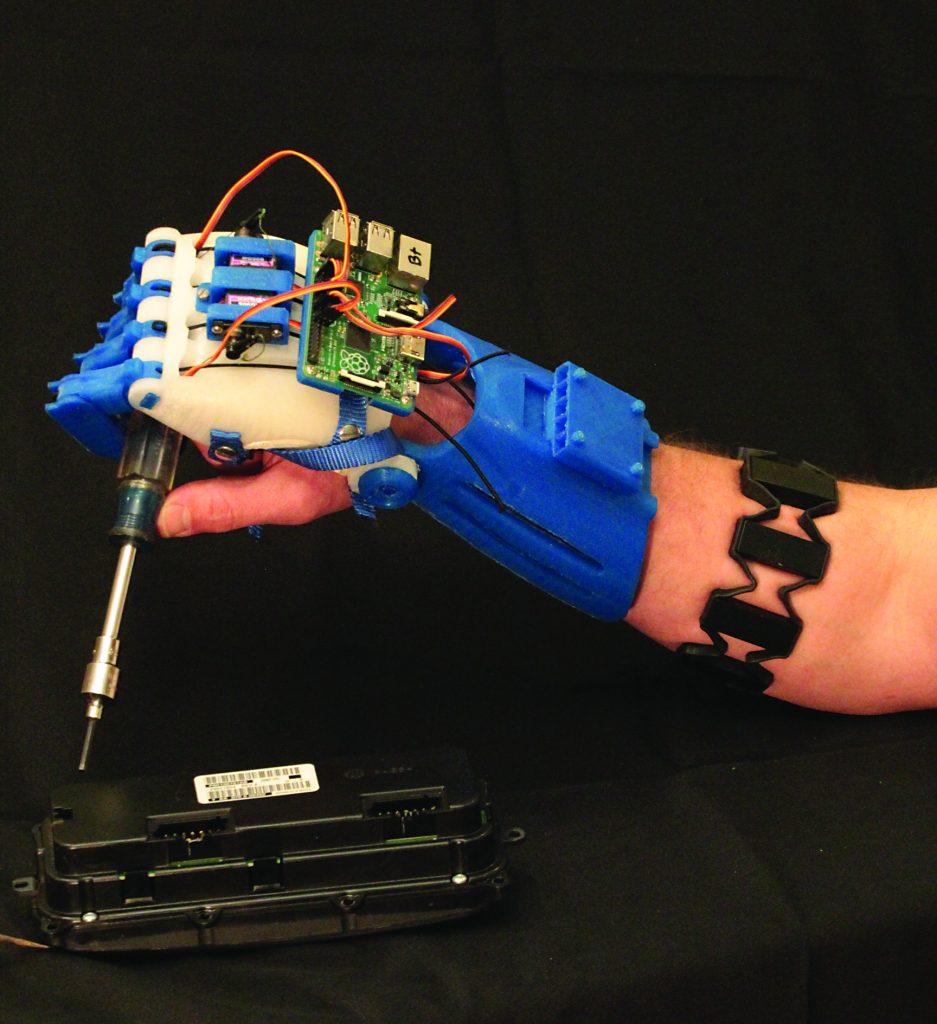

After collaborating with Armiger, Lesho, and others at APL, Haris figured out a way to bridge that gap. Using open-source technology, he was able to incorporate advancements like pattern recognition, wireless control, machine learning, and multidigit actuation into upper-extremity prostheses for a fraction of the price.

Haris’s advanced 3-D printed prototypes, for example, cost $500 or less to produce. Comparable devices not created using a 3-D printer might cost tens of thousands of dollars.

The open-source component is critical, not only in providing more affordable prostheses but also in giving scientists a toolkit—an “instructional guide,” notes Armiger—to continually make improvements.

Haris presented his project at the American Academy of Orthotists and Prosthetists 43rd Academy Annual Meeting and Scientific Symposium in March.