Teamwork by student inventors offers a way for the blind to play basketball.

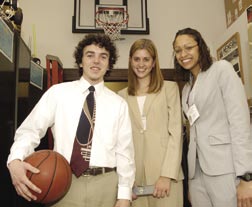

Using a prototype of an audible basketball and a sound emitter in the backboard, Mike Bullis, who is blind, could catch passes and sink buckets two out of three times in one test session. The basketball system for the blind he was trying out was designed and built by three Whiting School of Engineering undergraduates, two of whom are starters on the Johns Hopkins University’s women’s basketball team.

“There are people all over the country who are waiting for something like this,” says Bullis. He is the business services development manager for the project’s sponsor, Blind Industries and Services of Maryland, a group that aids the visually impaired. “There are blind athletes who want an audible ball. And there are schoolage children who can benefit from the hand coordination that comes from playing ball. Right now, blind kids can play with a ball, but only if someone is there to find it if it rolls away,” Bullis says.

The three students devised their system during a two-semester Engineering Design Project course in the Department of Mechanical Engineering. The project was particularly meaningful for Alissa Burkholder ’05 and Ashanna Randall ’05. Both played basketball for four years with the Blue Jays, a perennial Centennial Conference and NCAA Division III contender. As seniors, Burkholder, a shooting guard, and Randall, an All-Conference small forward, were major contributors to the team’s third straight season of 20-plus wins.

“I’ve been playing basketball so long, and it’s something I really enjoy. It’s nice to be able to share that with people who wouldn’t otherwise be able to play,” says Burkholder, who majored in Engineering Mechanics.

Randall and the third design team member, Steve Garber ’05, majored in Mechanical Engineering.

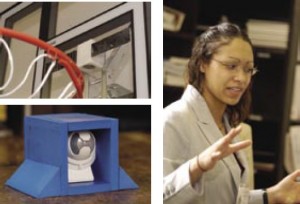

In their completed system, a large piezoelectric sound emitter—powered by a 9-volt battery and mounted behind the backboard—sends out low pulse tones to help players locate their shooting target. A remote control turns it on and off. A smaller sound emitter—embedded in the basketball and powered by five 3-volt button batteries—sends out a higher continuous tone to tell players where the ball is.

Bullis cautions that this prototype is not yet perfect, noting that the basketball’s sound pitch needs to be lowered for the comfort of players and to avoid echoes. He hopes to persuade a company to install the system as well in soccer balls and volleyballs.

A key hurdle for the three seniors was how to create a cavity to hold the electronics while keeping the ball airtight. “Weight was a consideration,” Randall notes. “If the device was too heavy, the ball wouldn’t bounce or roll properly.”

In their research, however, the students discovered the Spalding Infusion basketball, equipped with an airtight cylinder housing a small pump. The company provided several Infusion balls for the students to cut open and study, and later five more with just the cylinder. The students could then insert a sounding device and batteries in the small opening. But that meant a relatively high-pitched sounder. However, the students also came up with an idea for an alternate mini-speaker system that should emit a lower pitch, and provided details on it to Bullis’ organization for possible further development.

The students found their senior design project course to be a valuable experience. “We learned how to interact with real-world companies,” Burkholder said, as well as how “to get different ideas to mesh.” Following their graduation in May, Garber and Randall headed for research-related jobs and Burkholder will begin a master’s degree in mechanical engineering at Stanford University.

Their project was one of nine completed this year in the course taught by Senior Lecturer Andrew F. Conn ’57, ’59 MSE, ’64 PhD. Each team usually works within a budget of up to $10,000 to design a device, purchase or fabricate the parts, and assemble the final product. Corporations, government agencies, and nonprofit groups provide the assignments and funding.

If your company or organization would like some help from Whiting School seniors in designing a product or solving an engineering problem, contact Andrew F. Conn at (410) 516-6752 or by e-mail ([email protected]).