…that a new composite building material will crumble? For Lori Graham-Brady, the answer involves building ways to define and test the risks in structural systems.

We may look at a building and perceive solid slabs of concrete, but Lori Graham-Brady is seeing something else. She’s weighing the possibility of it cracking and failing. Just how many of our modern buildings possess this element of risk? According to the associate professor in the Whiting School’s Department of Civil Engineering, all of them do, though most thankfully in very small degrees.

“Everybody knows that risk is there when you build a building,” says Graham-Brady, “no matter how remote that risk is. There is no structure where there’s a 100 percent certainty of it never failing.” However, a greater problem, she warns, is the current climate regarding risk assessment. “If you ask somebody what an acceptable level of risk is, the answer is invariably zero,” she notes. “This is particularly true when a project is initiated by legislators who are very risk-adverse. This situation has been a real hindrance for civil engineers who want to measure risk more accurately in terms of the materials they use to build.”

Probability as a Tool

Graham-Brady began her professional career as a nuclear engineering consultant analyzing pressure vessels in power plants. She then earned a civil engineering PhD at Princeton University (1996), taking her interest in structural engineering and mechanics into a new direction: probabilistic mechanics, a discipline employing the use of probability to model the behavior of building materials for their structural reliability. Using computer models, an engineer can project the viability of a certain structural material, such as a steel I-beam, to withstand such variables as weight over time.

“Probability is a conceptual tool that tells us about how unknown and uncertain quantities can vary,” according to Graham- Brady. “Knowing that there’s uncertainty around our predictions, we assign a likelihood to different values around that prediction.”

In applying probability to structural engineering, a question might arise, for example, how likely is it that a certain type of steel is 10 percent weaker than the average? How can an engineer be certain if this is true? “The grade of steel that I’m using may have an assigned strength, but in reality that’s just an average value,” Graham-Brady explains. “If there’s some possibility of a flaw due to fabrication or human errors, that value could vary significantly. Probability theory simply is a way of assigning likelihoods to building weaker or building stronger.”

Civil engineers have long known that certain building materials, like metals, are more stable and thus more predictable. Other materials, concrete in particular, possess what Graham-Brady calls “significant random aspects.” Concrete has a wide range of variables contributing to its composition, from its mix of different aggregates (gravel materials) to the length of its curing time. As a result, she says, “The response in traditional engineering is to make the concrete-based structure a certain amount stronger than it has to be —or to assume an extra degree of loading, so we’re sure to cover any loads that we didn’t predict.”

Modeling Microstructural Stress

While such rules of thumb can apply with conventional materials, new composite building materials can prove challenging to use, even if they offer such obvious benefits as ease of use or lower cost. “Engineers are uncertain about them, because they haven’t built with them the way they’ve built with concrete,” says Graham-Brady. “They don’t know how variable these materials are, and then how to design structures using them.”

“There is no structure where there’s a 100 percent certainty of it never failing.” Lori Graham-Brady

The Day the Rows of Rivets Upzipped On April 28, 1988, at 24,000 feet above Earth, a large section of the upper fuselage of an aging 737 operated by Aloha Airlines peeled away in mid-flight. This classic example of fatigue cracking, notes Lori Graham-Brady, associate professor of Civil Engineering in the Whiting School, clearly showed the potential threat of small cracks that are difficult to detect in visual inspection. “This is a good example of how small-scale uncertainties (in this case flaws) can lead to large-scale catastrophic failure,” she says.

While the pilot somehow landed the plane safely, a flight attendant lost her life as a result of the explosive decompression. Noted Air Safety Week (November 12, 2001), “That industrychanging accident set in motion a comprehensive effort of inspections and, where necessary, repairs, to assure the structural integrity of pressurized fuselages.”

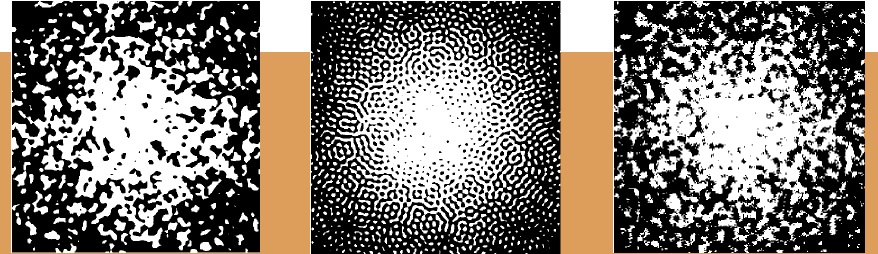

Graham-Brady’s current research focuses on providing a means to better understand the uncertainties of these newer random composite materials. Using computer models, her lab team is studying their microstructural properties by applying a load and then analyzing the resulting pattern of local stresses.

Through such modeling, Graham-Brady eventually hopes to develop a software application that is useful in answering structural reliability questions in the design of more complex structural systems— from bridges to automobiles. “We want to create a product that solves real engineering problems involved with structural behavior,” she says, as well as “any issue where they’re concerned about strength and the integrity of the materials used in enforcing that strength.”

While the current constraints of computer processing make such modeling difficult, Graham-Brady is confident that she will achieve her goal—and the value it provides. “Basically what I’m working on is risk management—assessing the risk of materials that may behave more poorly than expected, thus causing a negative impact within a structural system,” she says. “The insurance industry, for one, is very interested in this kind of issue from an underwriting standpoint. The outcome of this research will help define the probabilities that can cause structural systems to fail. We want to take that understanding of risk and do something good with it.”

To learn more about Lori Graham-Brady’s teaching and research, visit www.ce.jhu.edu/lori.