In a major advancement for 3D printing, researchers in the Whiting School of Engineering’s Department of Civil and Systems Engineering have developed a new 3D printer control method that promises to significantly improve 3D printing speed, precision, and material diversity for highly customized objects. The new control method, named Time Code, or T-Code, moves beyond the 66-year-old current standard, Geometry Code, by enabling 3D printers to perform complex operations without having to pause or interrupt the actual printing process.

Led by additive manufacturing expert Jochen Mueller, the team published its new approach in Nature Communications.

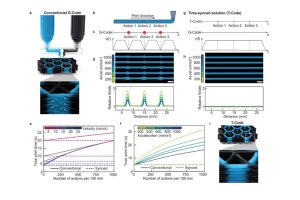

For decades, 3D printing has relied on Geometry Code, or G-Code—a programming language designed nearly a century ago to control computer-driven milling machines. While G-Code efficiently manages printer motion, it requires printers to stop before executing each line of printing instructions, causing bottlenecks and leaving visible defects in the final print.

“3D printing technology has advanced, but G-Code has struggled to keep up. It’s like asking a car to stop every time you want to change the song on the radio,” said Mueller. “G-code limits the use of multifunctional printheads, which allow users to mix materials or change the nozzle shape. Each additional function requires more commands in the programming language, causing more interruptions and defects in printed objects.”

In contrast, the T-Code programming synchronizes supplemental print functions with the printer’s motion, enabling continuous printing.

Using a Python script that separates G-Code commands into two distinct tracks—one with core print path instructions and one with additional commands for printhead functionalities—T-Code allows the printer to keep moving while it performs complex tasks, like creating a color gradient. This results in faster completion of customized prints and significantly reduces defects that result from frequent stopping and restarting of the printing process.

“We wanted to overcome the limitations that line-by-line printing controls impose on speed and precision,” said study co-leader, Sarah Propst, a doctoral student in civil and systems engineering.

“With T-Code, we’re able to achieve a level of sophistication that wasn’t possible before.”

The researchers say that T-Code also expands what’s possible to 3D print. By supporting advancements in printhead, material, and parts design, the new programming language can be used to create scalable and multifunctional structures across a variety of applications, including biological, electrical, mechanical, and optical.

“There’s already a broad array of printhead functionalities, and the demands on printhead controls are only expected to grow as 3D printing capabilities advance,” said Mueller. “These advancements will enable the creation of unprecedented structures with integrated functionalities, such as wearable electronic devices, smart prosthetics, and customized implants—but achieving this is contingent on sophisticated printhead control systems.”

T-Code works with both high-end and affordable 3D printers, potentially making advanced 3D printing more accessible. The script is complimentary to G-Code and can be added as a feature to existing printers without requiring expensive hardware upgrades.

Mueller and Propst anticipate that their new control method will be particularly useful in fields requiring significant customization, such as medical devices, robotics, and consumer products.