A team led by a Johns Hopkins materials scientist has uncovered how tiny particles grow in high entropy alloys (HEAs)—a class of materials made from at least five elements in nearly equal amounts. Reported in Intermetallics, their findings could help make these alloys stronger and more resilient to extreme environments, paving the way for improved materials in aircraft engines, energy systems, and consumer electronics.

“The complicated atomic structure of HEAs is characterized by the way these atoms arrange themselves, called short-range order. This organization breeds tiny grainy flakes within the material called precipitates,” says team member Elaf Anber, assistant research scientist in the Whiting School of Engineering’s Materials Characterization and Processing Facility. “How these atoms arrange around the tiny grains is chaotic and affects the behavior of the material, whether it’s strengthened or weakened. We want to understand how these precipitates interact with the atomic structures surrounding them so we can make better alloys.”

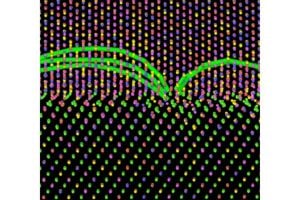

To start their investigation, the scientists created the alloy using a combination of aluminum, cobalt, chromium, iron, and nickel. They made the alloy into a thin film, heated it, and used two advanced techniques—Extended X-ray Absorption Fine Structure (EXAFS) and Extended Energy-Loss Fine Structure (EXELFS), performed in a transmission electron microscope—to analyze how the atoms are arranged in tiny, local regions. They also ran computer simulations to explore how different arrangements of the atoms affect the boundaries between structures in the alloy.

“Through this method, we discovered that when these new atomic structures line up within the alloy, they interact with original crystal structures in a way that we have never seen before. We also saw that the local atomic arrangement can control how precipitates align, which affects the strength and stability of the alloy,” says Anber.

This discovery can help scientists understand these alloys better and potentially tailor their microstructure to build safer, long-lasting, and more efficient products.

“We plan to explore how controlling the arrangement of atoms through composition or exposing them to heat could be used as a design strategy to tune precipitate formation and structure in HEAs. Since our simulations matched what we predicted the atoms would do, employing them with other HEAs could help us design materials for improved strength, corrosion resistance, and more,” says Anber.

The team also plans to investigate the unique connection between the precipitates and the metal’s original crystal structure and determine if these are found in other HEAs.

“Since we observed this non-typical orientational relationship between crystal phases, our next step is to investigate whether similar orientation relationships appear in other compositionally complex alloys, and whether we can intentionally induce them,” says Anber.

The team, led by Mitra Taheri, professor of materials science and engineering and director of the Materials Characterization and Processing (MCP) facility, includes Daniel Foley, postdoctoral researcher and study co-author. Collaborators also include researchers from Cornell University, the Materials Measurement Science Division at the National Institute of Standards and Technology, Drexel University, the University of Tennessee, Virginia Polytechnic Institute, and Stony Brook University. The work was funded by the Office of Naval Research, in part through the Multidisciplinary University Research Initiative (MURI) and other programs, through program managers David Shifler and William Mullins.