In an article appearing in Nature Reviews Materials, researchers including co-author Sreenivas Raguraman, a PhD student in the Johns Hopkins Department of Materials Science and Engineering, underscore the importance of including processing techniques when employing AI-based calculations for materials discovery.

“AI has accelerated how we predict material behavior, but these predictions don’t always match what we observe experimentally,” says Raguraman, who collaborated with Professor of Materials Science and Engineering Tim Weihs and Edward J. Schaefer Professor in Chemical and Biomolecular Engineering Paulette Clancy on his review. “How materials are made—their processing— ultimately determines the material’s performance. When processing is excluded, predictions may not translate to real-world outcomes.”

Raguraman highlights how AI and machine learning methods have drastically increased the rate of discovery of new materials, but these efforts rarely consider the processing techniques that determine the stability of a new material.

“If we don’t account for processing conditions, we can have all the right parts, and the material will still fail in the real world. It’s like baking a cake using all the right ingredients and following the package instructions—only to put it in the freezer instead of the oven,” he says.

Raguraman emphasizes that how materials are made is just as important as what they are made of. The team demonstrates this concept through case studies on biodegradable magnesium-based alloys used for orthopedic implants, where identical compositions can behave very differently depending on how they are processed. For example, certain heat treatments and deformation routes dramatically change corrosion resistance and mechanical strength without altering chemistry.

“Including processing in our AI-driven optimization effort will speed the development and adoption of new materials as more of the design process, both chemistry and fabrication, are considered,” says Weihs.

The authors justify their use of magnesium-based alloys because their experiments show it performs well in the body and is scalable for manufacturing. “However, widely used AI frameworks, such as DeepMind’s GNoME, focus primarily on predicting crystal stability and composition, not on processing pathways—an essential step in determining whether a material can actually be made,” says Raguraman.

To bridge this gap, co-authors Paulette Clancy and Maitreyee Sharma Priyadharshini, a professor at Virginia Tech, designed their own physics-based AI framework, called PAL 2.0. The model helps identify an alloy’s optimal processing conditions and better compositions for materials discovery. The Hopkins team applied PAL 2.0 to show how focusing on processing, treated as a design variable, can predict better alloy performance.

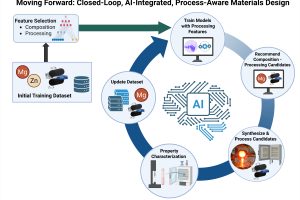

The team suggests two improvements to AI-driven materials discovery: improve the data that is used in these machine learning techniques and focus on process-aware materials design.

“Currently, processing methods are poorly documented when we are predicting alloy properties,” says Clancy. “Scientists should share all results—not just the successful ones—and ensure they’re accurate. Including that data can help develop AI models that can evolve to consider processing, bridging the gap between discovery and deployment to accurately make predictions about how an alloy will perform in real-world applications.”

Raguraman, Weihs, Priyadharshini, and Clancy collaborated with Adam Griebel, senior research and development engineer at Fort Wayne Metals, on this article.