A team including researchers from the Whiting School of Engineering’s Materials Characterization and Processing (MCP) facility has discovered that a particular class of materials can not only resist the damaging effects of nuclear radiation, but may evolve to become more resistant to the effects of radiation over time. The specialized alloys, called body-centered cubic (BCC) compositionally complex alloys (CCAs), could dramatically transform nuclear reactor design by lasting far longer than current materials, the team reports in Materials Letters.

“We hope this work can help us understand how CCA materials respond to radiation exposure—crucial information for the development of next-generation fusion and fission reactors,” said team leader Emily Mang, a materials science and engineering PhD student.

The research was inspired by current work in the field of radiation damage, and by Mang’s preliminary studies on how radiation affects nanocrystalline films—thin films made of heat-resistant metals with nanoscale crystal structures.

“In some of my prior work, we witnessed a complete lack of formation of radiation-induced defects at extreme damage doses. Instead of defect formation, we did see evidence of structural reorganization of the material. Researchers have theorized that these ultra-high temperature strength metals may also readily recrystallize due to inherent distortions in their crystal lattices; however, we had never actually seen this experimentally before,” Mang said.

The team began by mixing molybdenum-based alloys with varying fractions of niobium, tantalum, and tungsten, enabling the scientists to examine the material’s structural response as a function of increasing chemical complexity. The team then utilized an ion accelerator, the Danfysik Implanter at Los Alamos National Laboratory Center for Integrated Technologies (LANL CINT), to irradiate specimens with high-energy helium ions.

“The Danfysik Implanter is a high-energy particle accelerator and allows us to irradiate a choice target material. In our case, we chose helium irradiation to simulate the gaseous byproducts from fission and fusion reactions in nuclear reactors, and to investigate how these different metal alloys respond to void swelling — a process during which radiation creates tiny holes that cause the materials to expand,” said Mang. “Post-irradiation, we can analyze helium bubble formation using electron microscopy tools at the Materials Characterization and Processing Facility and evaluate radiation induced hardening with mechanical properties testing such as nano-indentation at the Hopkins Extreme Materials Institute.”

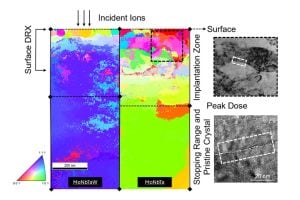

After irradiation, the team analyzed bubble formation in the samples using a transmission electron microscope (TEM), but ended up witnessing the formation of dynamically recrystallized grains near the sample surfaces that were more defined in complex alloys.

“Compared to our dilute alloy, the CCA sustained smaller bubble sizes after-irradiation and smaller hardness increase, indicating that the complex alloy inherently suppressed helium agglomeration and radiation-induced hardening,” she said. “Additionally, we noticed more defined surface recrystallization in the complex alloys, as well as a reduction in radiation-induced lattice distortion – the irradiated structure did not deviate as much from its original lattice parameter.”

The team is interested in whether these dynamic recrystallization properties may contribute to radiation-damage reduction. They aim to continue pursuing ways to understand whether the dynamic recrystallization process could help design materials that resist radiation damage.

The project was led by Mitra Taheri, professor of materials science and engineering at Johns Hopkins University and director of the MCP, and Yongqiang Wang, a collaborator from LANL.