Using a new type of Teflon, Johns Hopkins materials scientists have engineered a gas-detecting transistor capable of sensing toxic vapors in the air, paving the way for potential future applications in diagnosing diseases such as cancer and diabetes from a puff of human breath.

“The new Teflon-based transistor material we developed could monitor certain environmental gases, as well as biomarkers present in human breath. Our technology may provide valuable insights into environmental safety, as well as a person’s health status, by analyzing these gaseous compounds,” says team leader Howard Katz, professor of materials science and engineering at the Whiting School of Engineering.

Led by Katz and PhD student Riley Bond, the team’s project uses expanded-polytetrafluoroethylene (ePTFE)—a type of Teflon often used in outdoor clothing and electrical insulation materials—to enhance transistors’ performance and allow the material to detect gases. Their work, funded by ePTFE creators W.L. Gore & Associates, appeared in ACS Applied Materials & Interfaces.

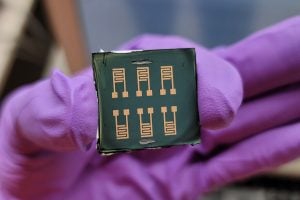

Teflon’s non-stick properties can pose challenges for its use in working devices. To solve this problem, Katz and his team discovered a semiconductor polymer that could coat the ePTFE’s unusually shaped fibers. They then used the ePTFE-polymer combination as the active material in a transistor—a semiconductor device that acts as a switch to control the flow of electric current.

The team found that not only did the transistors work better with the ePTFE and polymer combination, but the device also responded to the presence of nitrogen dioxide (NO2), a signal that it could monitor air quality.

“The key is in the Teflon’s irregular form, which increases its surface area, making it ideally suited for the detection of gas molecules because it increases opportunities for the molecules to interact with the material,” Katz said.

Riley Bond monitors the device, sealed in a chamber with NO2.

To validate the ePTFE device’s ability to detect gases, the researchers sealed it in a chamber with nitrogen dioxide (NO2), increasing the levels over time. The device’s current increased, indicating a strong response to the reactive gas.

This research with NO2 was boosted by the group’s participation in the National Science Foundation’s ICorps program, which equips engineers to commercialize their projects. After interviewing medical professionals and potential consumers, Katz and Bond discovered a market demand for a disease-testing device.

The researchers say this work is the first step towards developing a device that can detect formaldehyde and acetone, two toxic gases that may indicate the presence of cancer and diabetes, respectively. The device could greatly benefit the one in five Americans with undiagnosed diabetes by enabling early detection, potentially leading to treatment and better health outcomes.

“Our first objective was to create a working device on the ePTFE; as far as we know, no one has ever achieved this before,” Bond says. “Now, we aim to create something that will have a positive impact on general health.”