If you’ve ever watched a 3D printer in action, it’s mesmerizing—voxel by voxel and layer by layer, an object materializes before your eyes. But beneath this seemingly flawless process lurks a fundamental weakness: the interfaces where those voxels meet are inherently weak, leading to premature breaks or cracks. Now, civil and systems engineers at Johns Hopkins University have not only solved this longstanding problem; they’ve transformed these former flaws into a multifunctional feature.

“In 3D printing, interfaces are notorious for creating vulnerabilities,” said Assistant Professor in Whiting School of Engineering’s Department of Civil and Systems Engineering and corresponding study author Jochen Mueller. “The printed material either adheres too much or too little, resulting in structural weaknesses. It’s similar to the way spaghetti sticks together after cooking, but easily pulls apart. This creates flaws that limit the functionality of 3D-printed products.”

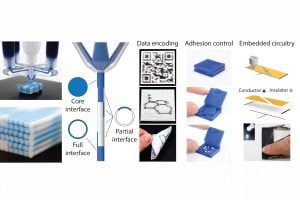

To combat this, the team has developed a new printing technique, known as voxel interface 3D printing, or VI3DP, that allows them to precisely control interfaces and how they function, including properties like adhesion—how well different layers or materials stick together. The team says its work, which appears in Advanced Materials, has the potential to customize the behavior of 3D-printed objects.

VI3DP uses a printhead equipped with a standard nozzle ringed by four additional nozzles. While the standard nozzle deposits material, these additional nozzles add a thin film of different material on top. This allows the interface between each 3D printed line to be controlled and customized in both single- and multi-material printing, eliminating the need for multiple printheads and unnecessary gaps or features in an object.

Beyond creating stronger prints, VI3DP also opens up a range of new applications for 3D-printed objects. In the study, the team demonstrates how they can integrate optical, mechanical, and electrical properties into the interfaces—all in a single print and without increasing weight, time, or cost.

Doctoral candidate Daniel Ames said that “adding mechanical, optical, or electrical properties is already possible using some 3D printing processes, including material extrusion and material jetting, but those processes require the properties to be added as entire voxels, rather than thin interfaces surrounding the voxels, significantly reducing throughput and resolution. Our method makes these properties feasible at a fraction of the voxel size, expanding the range and type of applications for soft materials.”

By embedding interfaces with physical properties, the new technology offers an unprecedented level of functional control in 3D printing, the researchers say.

“Interfaces are extremely crucial because of what they can enable,” said Mueller. “VI3DP has the potential to produce thinner interfaces, new material combinations, and integrated functions like complex 3D circuits, electromechanical devices, data-embedded composite structures, and print-in-place mechanisms with precise fittings.”

The team plans to investigate these potential improvements in future research.

“VI3DP is a strong foundation for future fabrication developments. We’ll be able to print complex structures that have never been possible before,” said Ames.

Study collaborators include Johns Hopkins University doctoral candidate Sarah Propst and visiting high school scholar Aadarsh Shah.