Engineering

Design Center

Making an Impact

Undergraduate student design is integral to Hopkins Engineering’s educational mission and commitment to solving critical societal problems.

Here, you won’t just take in knowledge

You’ll create it

By the Numbers

design courses

graduates

design-focused

student groups

Day projects

JHU Design Day 2025

Save the Date! Design Day 2025 is on April 29.

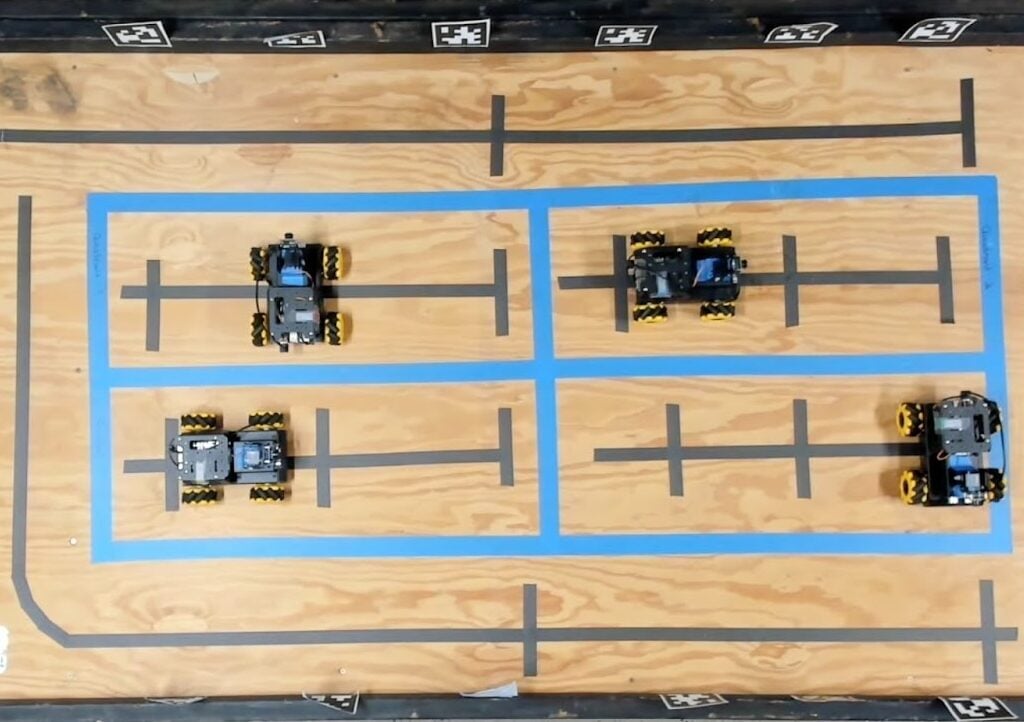

A school-wide annual event showcasing student design projects from every engineering department, student groups, and more.

JHU Design Day

Save the Date! Design Day 2025 is on April 29.

A school-wide annual event showcasing student design projects from every engineering department, student groups, and more

Testimonials

Taliyah

Biomedical Engineering

It is wonderful to watch students from different departments work together to support better engineering design opportunities at Hopkins.

To identify what can satisfy students from every engineering perspective has been both challenging and rewarding, as I’ve learned leading the multidisciplinary student advisory board for the Design Center.

Kareem

Computer Engineering

The First Year Seminar Design CornerStone helped me get exposed to a wide range of engineering disciplines and introduced me to all the makerspace and departments opportunities at Hopkins!

I am excited to take advantage of all the resources available to strengthen my engineering skills.

Alexander

Materials Science and Engineering

Being granted the opportunity to lead a design team has offered me the skillset necessary to apply both engineering and leadership skills in a collaborative environment. I look forward to utilizing these experiences in the medical device space!