Create

Design Project Gallery

Recycling Neolast: A Sustainable Spandex Alternative

- Program: Center for Leadership Education

- Course: EN.660.346 Multidisciplinary Engineering Design

- Year: 2025

Project Description:

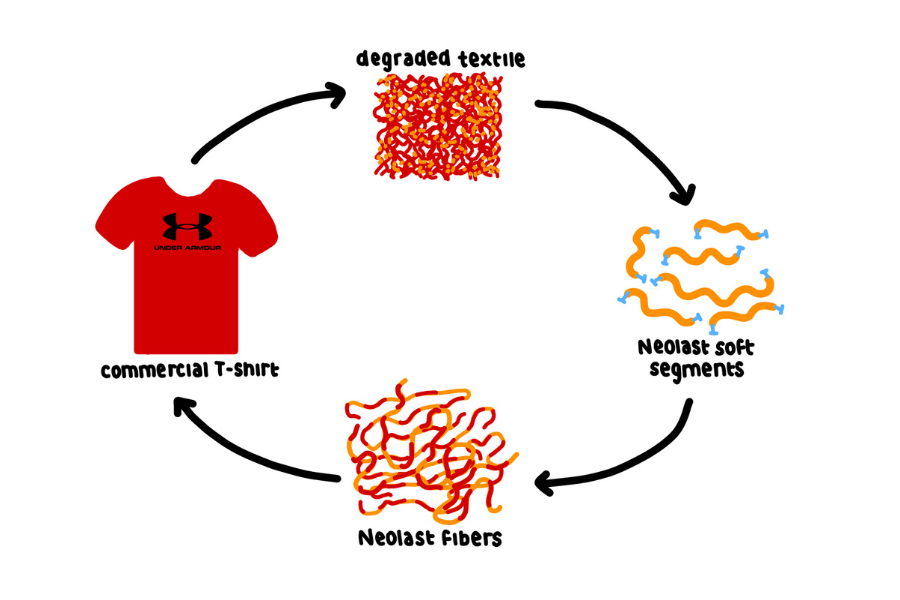

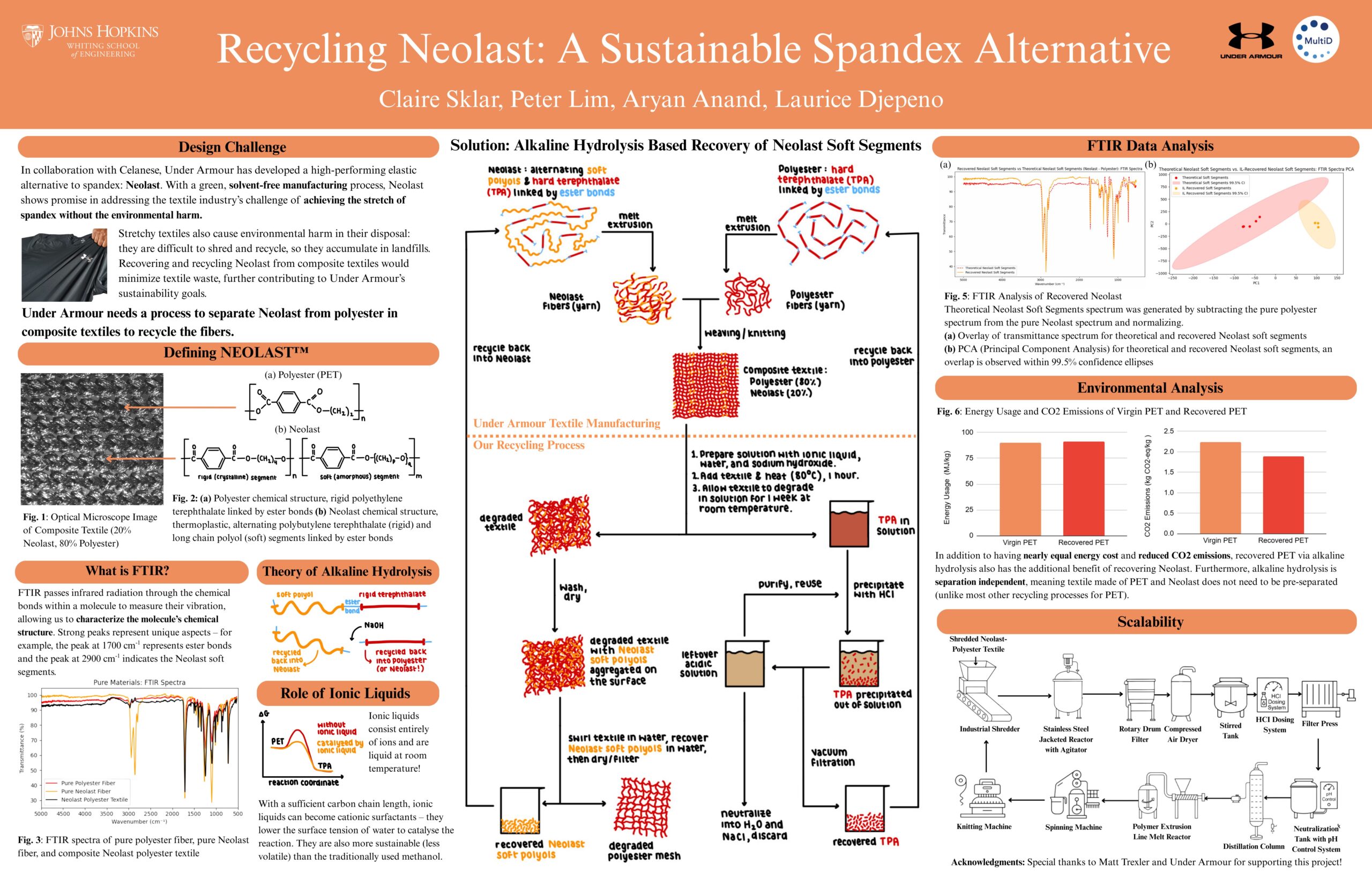

In collaboration with Celanese, Under Armour has developed a high-performing elastic alternative to spandex: Neolast. With a green, solvent-free manufacturing process, Neolast shows promise in addressing the textile industry’s challenge of achieving the stretch of spandex without the environmental harm. While the fiber manufacturing is already more sustainable, Under Armour has a high level of interest in recycling the fibers after they’ve been woven into composite textiles. Recycling stretchy fabrics like spandex is tough – they gum up machinery, tend to lose their properties post-processing, and recycling processes are typically low yield and expensive. Circumventing these challenges would allow them to make Neolast more green, reusing textile waste and preventing textile accumulation in landfills.