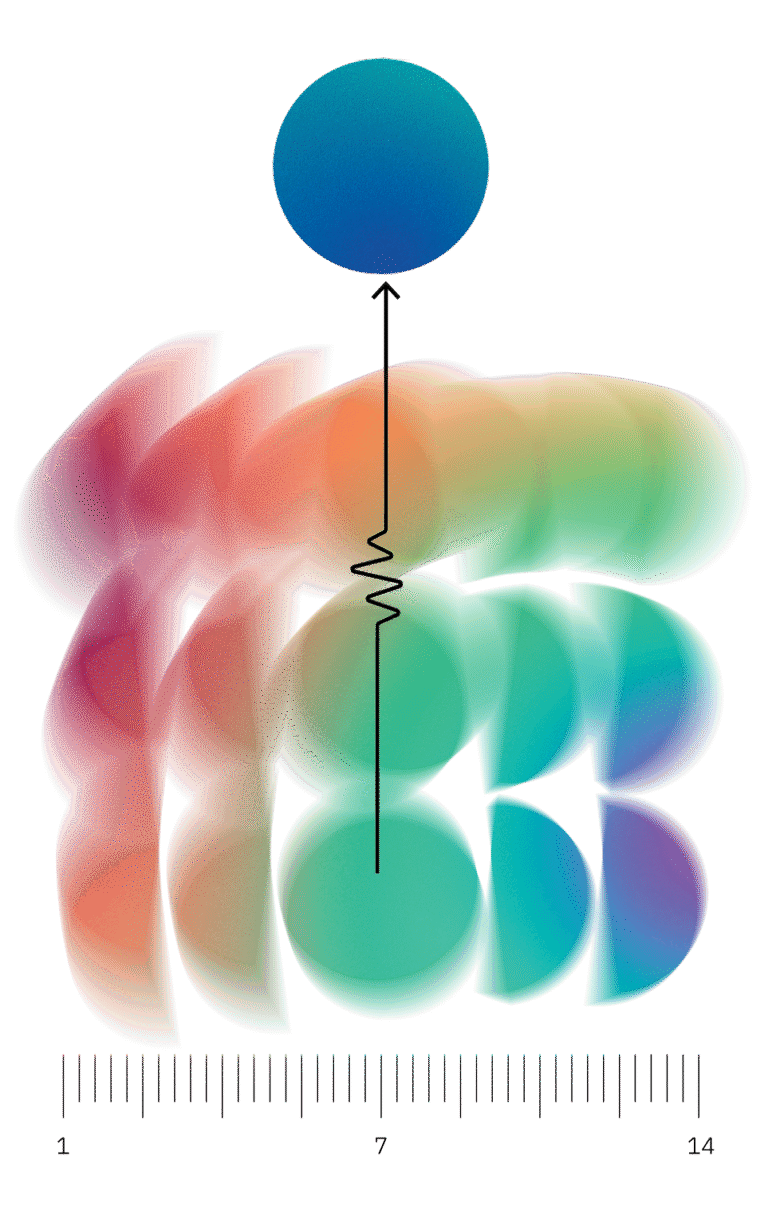

The process of cleaning wastewater, which flows down our drains and toilets, can drastically raise carbon dioxide (CO₂) levels in nearby waterways due to the release of CO₂ during the breakdown of organic matter and the use of chemicals that contain carbon. Environmental engineer Ruggero Rossi and his graduate student Nakyeong Yun found a new way to reduce levels of this common greenhouse gas by running the treated water through a process that uses an electrical current.

Their method, published in the American Chemical Society ES&T Engineering, marks a major step forward in decarbonizing water infrastructure.

Here’s how it works:

1. It taps into existing infrastructure..

CO₂-rich treated wastewater is pumped into a cell at the water treatment facility before the water is released. Because it is installed at the end of the process, treatment plants do not need to change their existing processes or equipment.

2. It uses electricity to remove carbon.

The electrochemical cell uses electricity to change the water’s pH in opposite directions at once, making it very acidic at the anode and very basic at the cathode. This chemical shift converts the inorganic carbon, in the form of bicarbonate, into CO₂ gas and solid metal carbonates. Both forms can be easily removed, unlike the original bicarbonate. The decarbonized water is returned to the environment. By remixing the solutions flowing out of the cell, the pH is returned to a neutral 7, thereby avoiding any issues downstream of the plant.

3. It can be tweaked to accommodate different wastewater properties.

Geography, seasons, and even the time of day can change the composition of untreated wastewater, meaning carbon-capture cells are not a one-size-fits-all solution. Team members identified key factors, such as conductivity and dissolved carbon content, that affect performance and optimized the system to work with real-world wastewater. Over 50 hours of continuous operation proved the system was stable.

4. It must be powered by renewables to be carbon-neutral.

With just a few adjustments—like tweaking the flow rate or electrode spacing—performance can be improved while keeping energy use low. However, the process still requires power. To ensure the approach stays carbon-negative, it must be powered by renewable energy. At larger scales, this could become a cost-effective addition to carbon removal strategies.

—LISA ERCOLANO