People

Research Scientist – Dr. Diego Muriel Delgado

Project Supervisor – Dr. Joseph Katz

Introduction

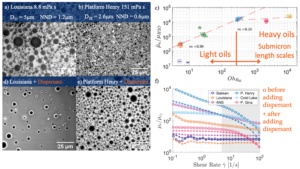

It is commonly believed that emulsification of oil slicks after a couple of days renders the use of dispersant ineffective. Yet, there is very limited data on the interactions between dispersant and emulsified oil under breaking waves. As a first step, we have recently investigated the time evolution and effects of adding dispersant on the microscopic morphology and bulk viscosity of salt water-in-crude oil mechanically mixed (in a beaker) emulsions involving a series of crude oils and dispersant concentrations (Muriel & Katz, 2021 and 2023). Samples of our findings are summarized briefly in Figure 1. Both light and heavy oils emulsify water, however the entrained droplet sizes (measured using fluorescence microscopy), nearest neighbor distance (NND), and entrained water volume fraction vary with oil properties. For example, the water droplets and their NND are significantly smaller for the heavy oil emulsions (compare Figure1a and b). Trends of the viscosity of the emulsified oils plotted vs. the Ohnesorge number (, where m, r, s, are the oil viscosity, density, and interfacial tension with water, respectively, and d is a characteristic length scale – the droplet Sauter mean diameter) in Figure 1c show different trends for light and heavy oils. The increase in viscosity is faster for the light oils, where the water droplets are larger and entrained volume is higher, and milder for the heavy oils. All the emulsions exhibit non-Newtonian behavior, i.e., their viscosity decreases with increasing shear rates (Figure 1f). That means that emulsification and subsequent interaction of the dispersant with waves strongly depend on the shear rate (or wave energy). In fact, when waves are sufficiently powerful, they actually break/fragment the emulsions.

The mechanical mixing experiments have also shown that the effect of adding dispersant to emulsions, even at low concentrations (DOR of less than 1:1000), also varies substantially with oil properties. For light oils, adding dispersant causes phase separation, i.e., the water is extracted out of the emulsion (compare Figure 1a to 1d), drastically reducing its viscosity (e.g. Louisiana Oil in Figure 1f). In contrast, dispersant has little effect on the emulsion morphology (Figure 1b to 1e) and viscosity for heavy oils, e.g., compare the Cold Lake and Platform Gina data in Figure 1f. Hence, dispersants may be used for decanting of light oil emulsions, but not of heavy ones.

Figure 1. a) and b) fluorescent light microscopy for Louisiana (light) and Henry (medium) oil-based emulsion, respectively. c) average crude oil emulsion viscosity normalized by that of seawater as a function of Ohnesorge number. d) and e) Louisiana and Henry oil-based emulsions with premixed dispersant, respectively. f) emulsion viscosity with and without premixed dispersant normalized by that of the fresh crude oil as a function of shear rate. Here, me and mcf are the viscosity of the emulsion and of the fresh crude oil, respectively.

PUBLICATIONS

- D.F. Muriel, J. Katz, Time Evolution and Effect of Dispersant on the Morphology and Viscosity of Water-In-Crude-Oil Emulsions, Langmuir, 37 (2021) 1725-1742.

- D.F. Muriel, J. Katz, Effects of crude oil properties and dispersant on the microstructure and viscosity of seawater-in-oil emulsions, Langmuir, 39 (2023) 2043–2062