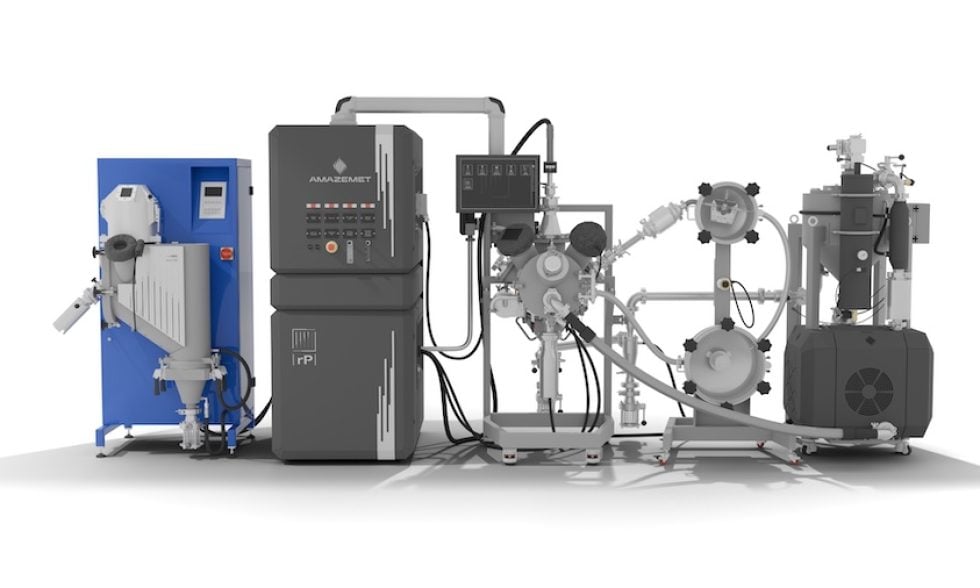

The powder atomizer is used to create custom metal powders from any alloy and feedstock form in research quantities. Raw elements or scrap can be used to prototype new alloying systems as ingots or powders. Failed printouts, unused powder or scrap can be recycled back into fine, highly spherical powder. The platform features:

- Induction module with a graphite crucible to process alloys with melting T up to 1300 °C.

- Arc/Plasma melting module for arc melting alloys with melting temperatures up to 3500 °C and making rods/buttons, suction casting or atomizing them into highly spherical metal powders.

- 40 kHz and 60 kHz frequency generators to obtain desired powder range using ultrasonics

- Gas recirculation system