Self-Assembled Morphogenic Metal Coatings

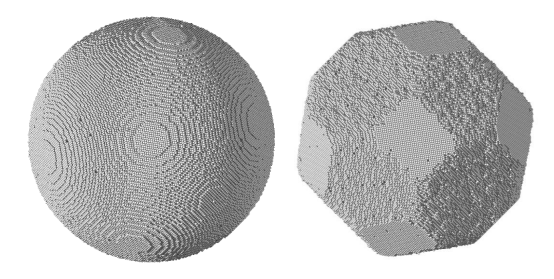

Kinetic Monte Carlo Simulations of Diffusion

Using an in-house C++ code, we can study the complex diffusion processes that occur for NiTi-Cr coatings under an electric potential. While our code works for this specific case it is also being used for more general cases to better understand fundamental science questions including the impact of second near neighbors on kinetic events, the effect of bond energy on the final equilibrium shape, and much more!

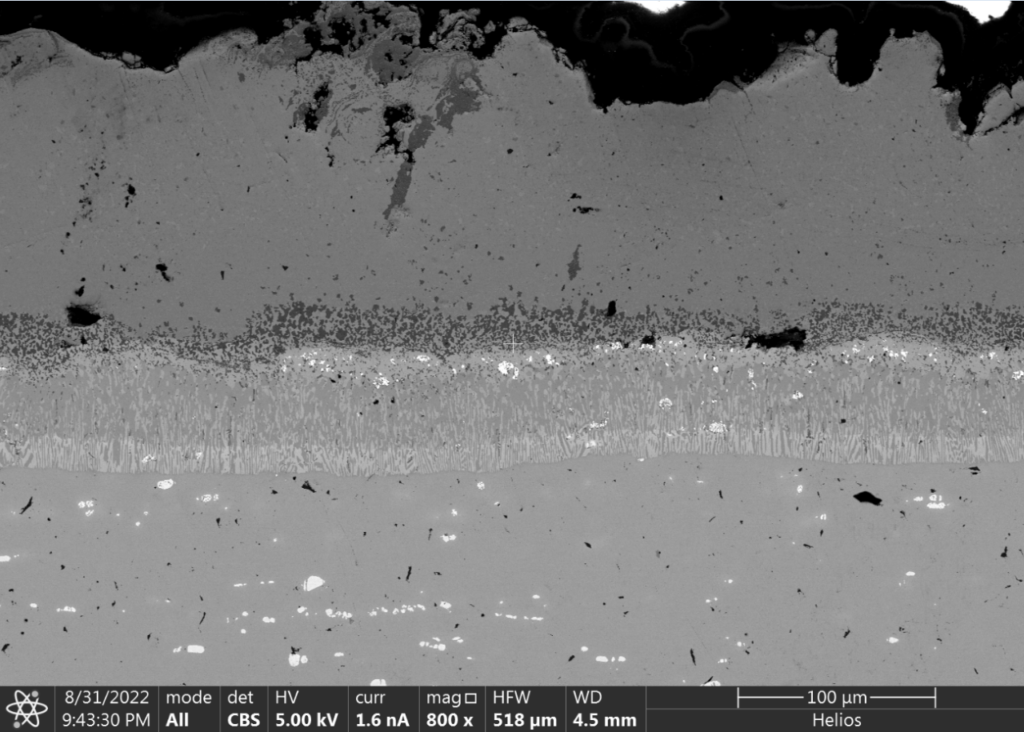

Corrosion and Fatigue Resistant Metal Coatings

We are studying a class of multicomponent metal alloy coatings for use in environments subjected to simultaneous corrosion and fatigue. Systems of Ti-Cr deposited on Ni and Fe-based substrates are being investigated to optimize the coating’s strength under axial fatigue and electrochemical resistance. The evolution of the phases and compositions at various treatment conditions are being studied by a combination of optical microscopy, electron microscopy and energy-dispersive x-ray spectroscopy.

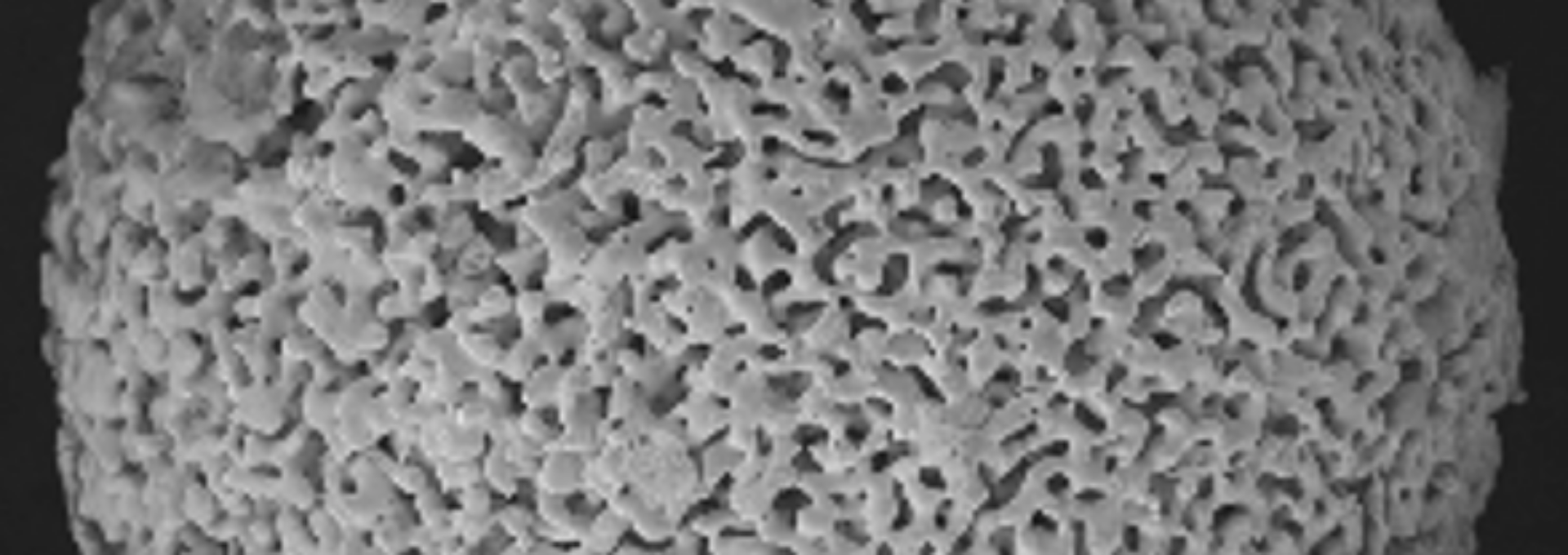

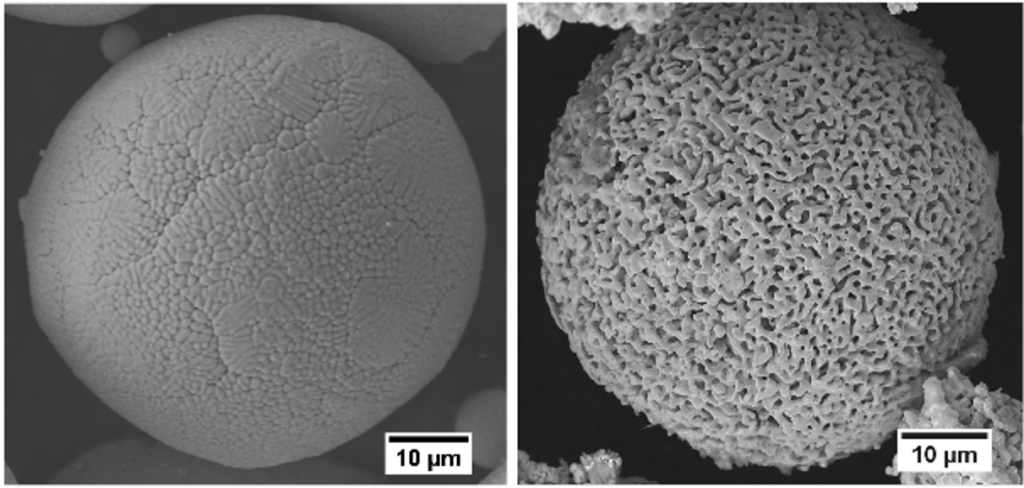

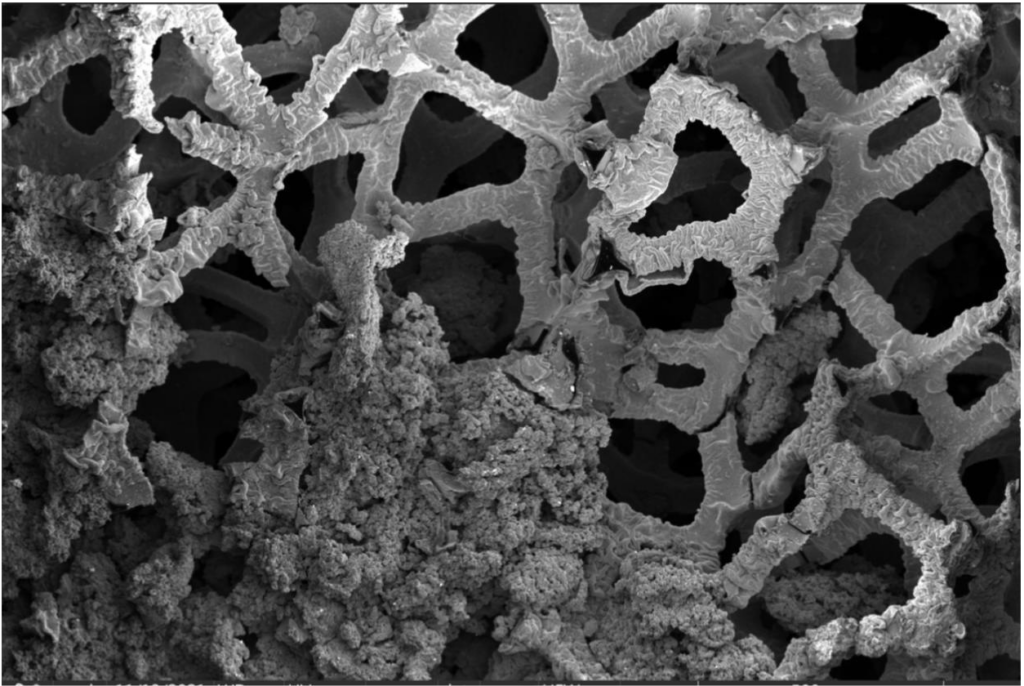

Powder Based Dealloying

Dealloying is a corrosion process by which we can fabricate nanoporous and nanocomposite materials with unique material properties and many potential applications, but the technique still has some limitations, most notably in scalability. Current work aims to address these processing hurdles and assess potential solutions such using a quaternary dealloying system (binary precursor alloy and binary solvent alloy) as well as a new powder-metallurgical approach to both liquid metal and solid-state dealloying. We are also exploring the potential for dealloying techniques to be integrated into laser-based additive manufacturing processes.

Ralph O’Connor Sustainable Energy Institute (ROSEI)

Combatting carbon dioxide output is one of the main pillars ROSEI is founded upon. ROSEI’s main focus in this area is on a novel attempt at extricating the carbon in CO2 and converting it into a form of solid carbon useful in applications ranging from farming to construction. These efforts are house under an initiative titled “Negative Carbon Carbon (NC2). You can learn more about ROSEI’s carbon efforts here and see Professor Erlebachers ROSEI landing page here.

Magnesium-based Carbon Capture

Addressing the need for a carbon sequestration process which turns carbon dioxide into a commercially useful form of carbon, this work explores the magnesium – carbon dioxide reaction under controlled conditions. Magnesium is one of the few materials which is capable of fully reducing carbon dioxide to carbon. Using a porous foam as a nucleation site, preliminary work showed that carbon deposits as a solid and grows to fill the pores. Further work aims to understand how this process changes with temperature, to see if the order of the carbon structure can be controlled.

Methane Decomposition

By mass, natural gas (NG) is the most-extracted material on the planet. Natural gas extraction releases large amounts of methane, NG’s main ingredient and a potent greenhouse gas, which can be burned for energy generation or converted into hydrogen (H2). Methane pyrolysis is an energy-efficient, environmentally friendly approach to produce emission-free H2 and carbon products—but to be commercially viable, these products must be useful for large-scale applications. Using our novel scale up process we convert natural gas into hydrogen and solid carbon with no water input while reducing carbon dioxide (CO2) emissions. ETCH, INC, is commercializing the process, which is expected to produce H2 from NG at costs comparable to the state-of-the art commercial technologies, while lowering energy input, reducing CO2 emissions, and producing high-value pure carbon materials.